Introduction: When Manufacturing Parameters Become Therapeutic Variables

In modern pharmaceutical technology, the distance between formulation science and clinical outcome is far shorter than it once appeared. A decision made at the level of processing pressure or mechanical conditioning may ultimately shape patient experience, therapeutic reliability, and even adherence. Electrospun nanofibrous orally dispersible films (ODFs) represent a striking example of this convergence between engineering precision and medical purpose.

Orally dispersible films were introduced to address a deceptively simple problem: how to deliver medication safely and effectively to patients who struggle with conventional solid dosage forms. Pediatric and geriatric populations, patients with dysphagia, and those requiring discreet administration all benefit from dosage forms that dissolve rapidly in the oral cavity without water. Yet achieving rapid disintegration while maintaining mechanical integrity is not trivial.

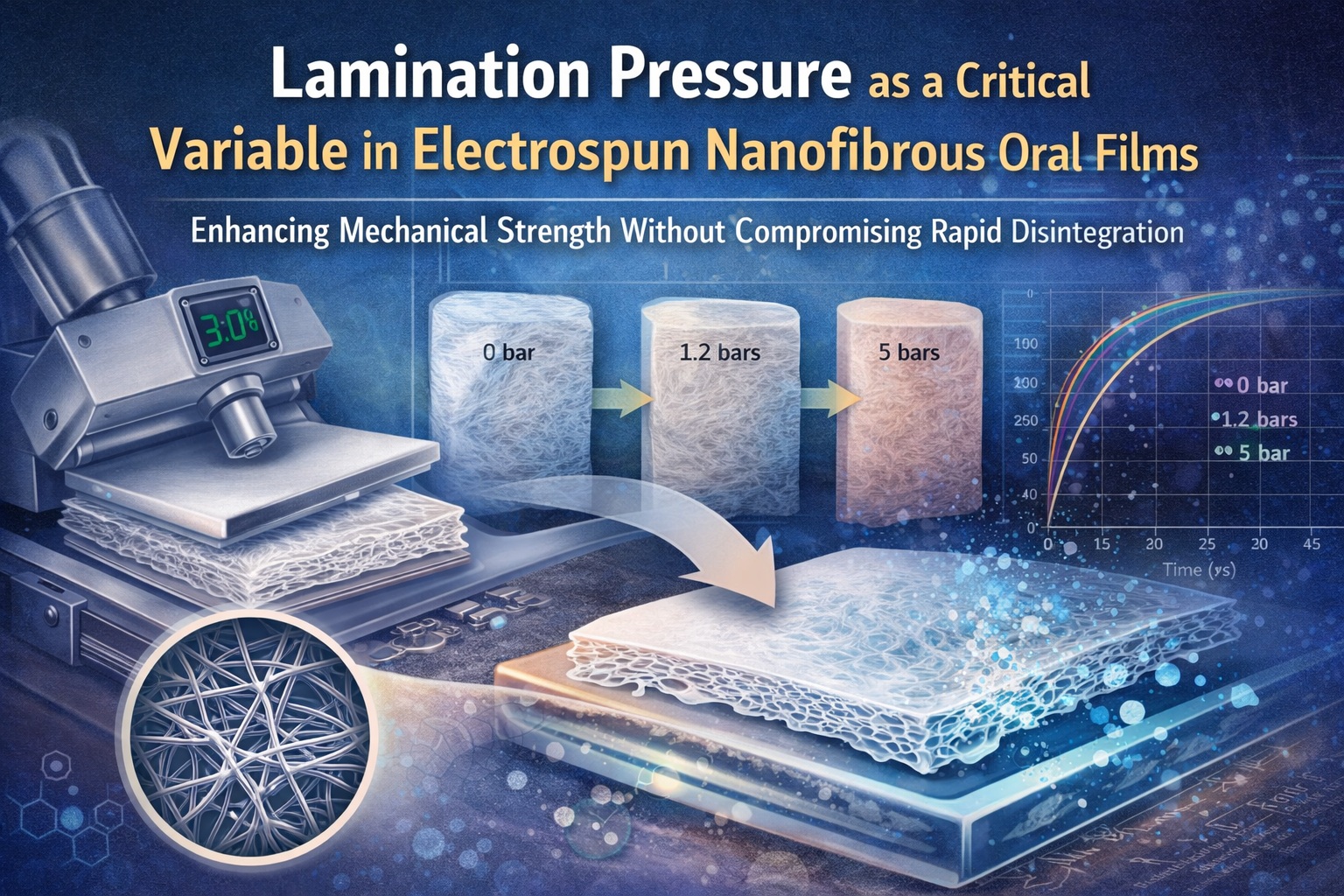

Electrospinning has emerged as a powerful technique to meet this challenge. By producing highly porous nanofibrous matrices with enormous surface area, electrospinning enables ultrafast film disintegration and enhanced dissolution kinetics. However, the same porosity that enables performance also introduces fragility. This is where lamination pressure—often treated as a secondary processing step—becomes a decisive variable.

Electrospun Nanofibrous Films: A Structural Advantage with Practical Vulnerabilities

Electrospun films differ fundamentally from solvent-cast or hot-melt extruded films. Their architecture consists of intertwined nano- and microfibers forming a highly porous network. This structure allows saliva to penetrate almost instantly, leading to rapid film breakup and exposure of the active pharmaceutical ingredient (API).

From a biopharmaceutical standpoint, this is ideal. High surface area accelerates wetting, polymer dissolution, and drug release. For poorly soluble drugs, such as BCS class II compounds, electrospinning offers a pathway to improved apparent solubility without chemical modification of the API.

Yet this same architecture creates challenges during handling, packaging, and large-scale manufacturing. Non-uniform thickness, low tensile strength, and sensitivity to humidity can compromise dose uniformity and processability. Without intervention, electrospun films may tear, delaminate, or crumble under minimal mechanical stress. Lamination is introduced precisely to mitigate these vulnerabilities.

Lamination Pressure: From Mechanical Reinforcement to Structural Transformation

Lamination involves compressing electrospun layers under controlled pressure to produce a more cohesive film. At first glance, this appears to be a straightforward mechanical reinforcement step. In reality, lamination pressure induces profound microstructural changes that influence film performance far beyond tensile strength.

As pressure increases, nanofibers are forced closer together, reducing void volume and increasing material density. Fiber–fiber contact increases, and in some cases, partial fiber fusion occurs. These changes directly affect Young’s modulus, maximum strain tolerance, and brittleness of the film.

Importantly, lamination does not merely “flatten” the film. It reshapes the internal architecture in ways that alter disintegration dynamics, moisture sensitivity, and handling behavior. The study demonstrates that lamination pressure is not a binary variable (laminated vs. non-laminated), but a continuum with distinct performance regimes.

Mechanical Properties: Finding the Balance Between Strength and Flexibility

Mechanical testing reveals a non-linear relationship between lamination pressure and film performance. As pressure increases, stiffness—as reflected by Young’s modulus—also increases. This is expected: denser materials resist deformation more effectively. However, stiffness alone does not define usability.

Maximum strain and stress resistance are equally important. Films must withstand cutting, packaging, and patient handling without fracturing. The data demonstrate a clear optimum at moderate lamination pressure, where tensile strength and elasticity are maximized simultaneously.

At excessively high pressures, films become brittle. Maximum strain drops sharply, indicating loss of flexibility. From a manufacturing perspective, such films may fracture during processing. From a patient perspective, they may crack during handling or feel unpleasant in the mouth. The implication is clear: more pressure is not always better.

Humidity Conditioning: The Hidden Variable in Film Performance

Orally dispersible films are inherently hygroscopic. Their polymeric matrices absorb moisture from the environment, which can act as a plasticizer and alter mechanical behavior. Conditioning experiments reveal that relative humidity significantly modifies the effect of lamination pressure.

At higher humidity levels, films become more elastic, but also less dimensionally stable. Water molecules disrupt polymer–polymer interactions, reducing stiffness and increasing strain tolerance. Interestingly, the mechanically optimal lamination pressure remains consistent across humidity conditions, suggesting a robust processing window.

This finding has practical significance. It implies that manufacturers can identify an optimal lamination pressure that remains valid across realistic storage conditions, simplifying scale-up and quality control.

Disintegration Time: Compression Without Compromising Speed

A central concern when densifying ODFs is whether mechanical reinforcement compromises rapid disintegration. The study addresses this question directly and convincingly.

As lamination pressure increases, disintegration time increases as well—but within clinically acceptable limits. Even at the highest pressure tested, disintegration remains well below the threshold defined by pharmacopoeial standards. The fastest films disintegrate in fractions of a second; the slowest in a few seconds.

This modest delay reflects increased density and reduced porosity. Crucially, the relationship is predictable and controllable. Manufacturers can fine-tune disintegration time without sacrificing regulatory compliance or patient convenience.

Dissolution Kinetics: Independence from Lamination Pressure

Perhaps the most clinically reassuring finding is that lamination pressure does not affect dissolution kinetics of the API. Once the film disintegrates, drug release is governed by particle dissolution rather than film structure.

This decoupling of disintegration and dissolution is a major advantage of electrospun systems. Unlike tablets, where compression affects both disintegration and dissolution, electrospun films allow independent optimization of mechanical strength and drug release behavior.

For clinicians and formulators alike, this means that mechanical optimization does not risk altering therapeutic performance—a rare and valuable property in dosage form design.

Solid-State Stability: Preserving the Identity of the Drug

Analytical techniques including differential scanning calorimetry, X-ray diffraction, and HPLC confirm that lamination does not induce chemical degradation or polymorphic transformation of the API. Tadalafil remains crystalline and chemically intact across all tested pressures.

This is not a trivial observation. Mechanical stress can induce amorphization or degradation in sensitive compounds. The absence of such effects underscores the suitability of lamination as a gentle post-processing step for electrospun films.

Minor changes observed in excipient crystallinity at very high pressures further reinforce the concept of an optimal pressure window. Beyond this window, structural changes may compromise mechanical behavior without offering additional benefit.

Manufacturing Implications: From Laboratory to Production Line

From an industrial perspective, the findings provide a clear roadmap. Lamination pressure can be used strategically to:

- Improve dose uniformity by reducing thickness variability

- Enhance mechanical robustness for automated handling

- Preserve ultrafast disintegration and dissolution

- Maintain chemical and physical stability of the API

The identification of an optimal pressure range is particularly valuable. It reduces trial-and-error during scale-up and supports quality-by-design principles.

Clinical Relevance: Technology Serving Patient Needs

Ultimately, the success of any dosage form is measured at the patient level. Electrospun ODFs laminated under optimal pressure offer a rare combination of attributes:

- Rapid oral disintegration

- Reliable dosing

- Improved handling and packaging

- Enhanced acceptability for vulnerable populations

In this context, lamination pressure is not merely a technical parameter—it is a contributor to therapeutic success.

Conclusion

Lamination pressure exerts a profound yet controllable influence on electrospun nanofibrous oral films. When applied within an optimal range, it enhances mechanical performance without compromising disintegration, dissolution, or drug stability.

This work demonstrates that thoughtful control of post-processing parameters can transform fragile nanostructures into clinically robust dosage forms. In doing so, it reinforces a broader principle of pharmaceutical science: precision in manufacturing is inseparable from quality in therapy.

FAQ

1. Why is lamination necessary for electrospun oral films?

Because electrospun films are highly porous and fragile, lamination improves mechanical strength and processability without sacrificing performance.

2. Does higher lamination pressure always improve film quality?

No. Excessive pressure increases brittleness and reduces flexibility. An optimal pressure range provides the best balance.

3. Can lamination affect drug release or stability?

Within the studied range, lamination does not affect dissolution kinetics or chemical stability of the drug.